Lubinski Meerschaum Pipe in Floral Sculpted Sea Foam

Regular price €198,00 Sale

Sea foam made from whole block

Finish: Smooth

Group 6: Medium

Shape: Bent Sculpted Floral

Meerschaum is generally known as the “white goddess” and its admirers particularly emphasize its performance. It is composed of hydrated magnesium silicate (scientifically called sepiolite) which is found in Turkey and Tanzania.

Its origin is uncertain, but it is assumed that the calcareous water of the rivers eroded the magnesium stones and deposited the mud that formed. Possible geological changes would have determined the change in the course of the river, leaving behind, at a depth between forty and eighty metres, the alluvial deposits which would then have been pressed into blocks following the pressure exerted by the overlying tectonic masses.

If on the one hand there are countless legends about the date of birth of the first pipe made from this particularly light material, on the other hand it is certain that the first European meerschaum pipes were manufactured in Hungary and imported by some aristocrats to Vienna, where a meerschaum processing center developed. Around 1870, over two hundred companies located in the Austrian capital were producing hydrated magnesium silicate pipes, and the term “Vienna foam” was introduced into pipe literature.

The best meerschaum used in pipe making is the block foam from Turkey. The material originating from Tanzania is geologically much younger than the Turkish one and does not give the same yield and does not even have the same truly white color as the Turkish one, extracted mainly in the region surrounding Eşkisehir. For low-priced pipes, pressed foam is also used, consisting of foam waste held together by the pressure exerted and the binder. The lower quality consists of mass meerschaum which also consists of waste, but. contrary to what was illustrated above, they are ground into a pulp which, once water, potassium silicate and potassium salts have been added, is boiled for processing purposes.

Block meerschaum pipes, which we will talk about now, are usually made on a lathe. First the blocks are cut to the right size, softened in water and finally, while still wet, turned and drilled and often carvings or ornaments are applied to them. While in the past the turned or sculpted heads were dipped in whale white, today they are instead dipped in lightened white wax. Foam pipes have won over many smokers because they do not require break-in, do not suffer burns and allow the tobacco to retain its aroma. So the pipe "doesn't mind" if the smoker smokes different tobaccos. The desire of most smokers is for the color of their "white goddess" to gradually change, first becoming amber, then pink, finally arriving at dark brown. To achieve this objective, however, it is necessary to smoke the pipe several hundred times, keeping in mind that the first time must be smoked with great caution. In fact, if the head of the pipe overheats, the smoke condensate settles on the bottom and it is no longer possible to obtain a uniform color. In the past it was generally recommended not to touch the head of the pipe while smoking as fingerprints caused stains.

Some books even recommend touching the pipe only after putting on soft wire gloves. The expert Otto Pollner recommends instead smoking the pipe by holding it in your hand - as long as it is clean - as this would allow you to constantly keep the temperature under control and contribute to a uniform heat distribution thus obtaining the much desired red-brown hue more quickly. Many prejudices, many outdated maintenance instructions and many incorrect recommendations for use have led to a decline in the popularity that the foam pipe enjoyed in the past. In reality, there are few rules to respect, one is for example that these fragile pipes must not be emptied by hitting them against hard objects, but this also applies to briar pipes.

There are now only a few foam pipe manufacturers left. One factor that has favored this trend is that, when Turkish politicians realized that Turkey is one of the few countries to have deposits of the precious foam, they issued a ban on the export of the raw material to incentivize local producers. Regardless of the fact that the ban is sometimes harshly and sometimes leniently enforced, some European manufacturers legally circumvent current legislation by purchasing sea foam in Turkey, where they begin processing it and then export it. The finishing is carried out in Austria, Switzerland or France. Since the rights to the name of the long-established Viennese house Andreas Bauer were sold, Sedat Konçak produces approximately 1,500 pipes per year marked with that brand and 8,500 marked with his own name. The Lubinski catalog offers foam pipes, exclusively Turkish block pipes, made exclusively to a design by the Sekergioglu brothers from Eşkisehir. Usually the classification by value of foam pipes, in the classic shapes, takes into account the size of the rough block, and mainly the height of the bowl. Hence our classification into groups from 5 (small) to 10 (giants).

All individually packaged with a unique artisan process.

Anno di Produzione: 2023

Nazione di provenienza: Türkiye

Forma: BENT

Filtro: No

Grandezza pipa: Average

Peso (Gr): 48

Materiale bocchino: Yellow methacrylate

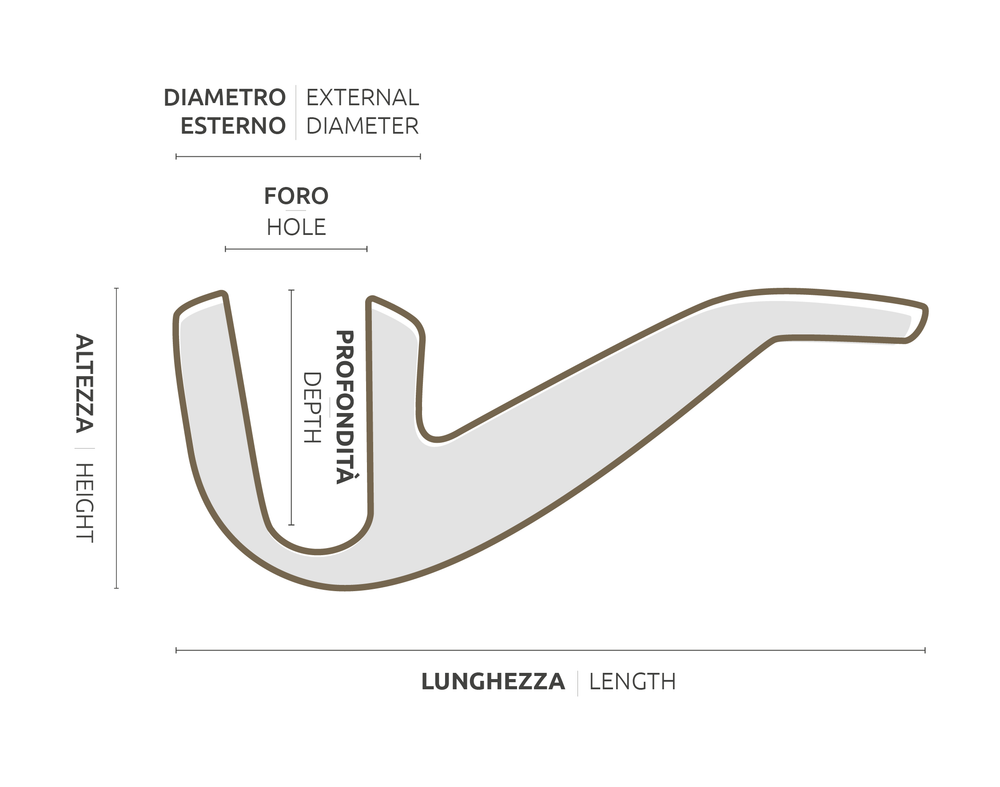

Lunghezza (mm): 134

Altezza fornello (mm): 52

Diametro esterno (mm): 40

Diametro foro (mm): 20.20

Profondita foro (mm): 42